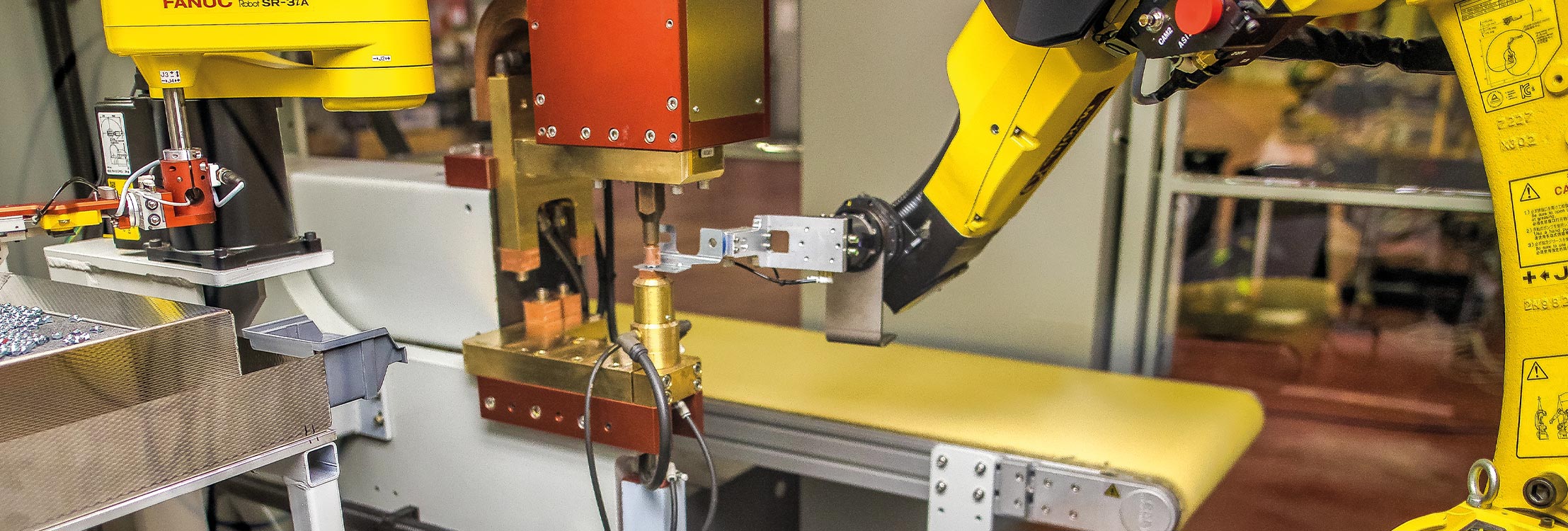

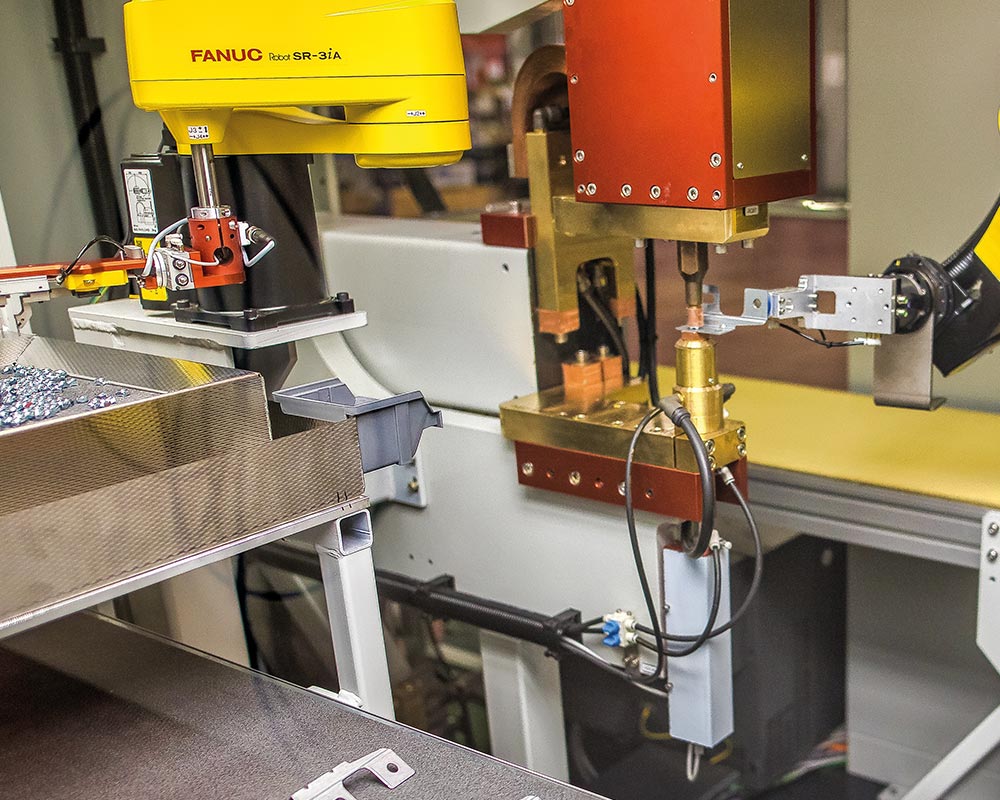

Vibratory feeder

Dengensha Vibrating feeders are designed and built to feed all kinds of weld nuts, such as hexagon, circular, collared flange and T nuts.

Features

- High feed rates

- Purpose-designed separators for realibility

- Flexible feeding methods make it easy to feed a nut to a distant point up to 10m from the separator consistently as the separated nut is fed by airthrough a vinyl tube to the feed unit.

- Nut is held firmly at the end of the magnetised spindle and fed positively to a locator even if the feeding angle and/or speed changes.

Other features

- Vibratory nut selection for all kinds of nuts

- High feed and reliability rates >1 second

- Single or dual (simultaneous) feeding

- Special dual (left, right, both) option on independent models

- Siemens controls (standard)

- Easy to use in manual or robotic systems

- Bulk hopper 7 litres

- (M6 DIN = 8,000)

- (M8 DIN = 4,000)

- CE specification

- Trained support network

- Onboard programming

- Program back-up and recover

- Selection capability Up to 60 per min

- Feeding stroke 200mm

- Feeding angle 30º -60º adjustable

- Power Supply 110V 50Hz or 230V 50Hz

- Control voltage 24V DC

- Air Supply 5 bar

- Standard Bulk hopper

Options

- 300mm stroke

- Vinyl dust cover

- Tube length up to 10m

- Orientation guide