Lerocon Confeeder Compact NW

Lerocon Confeeder Compact NW

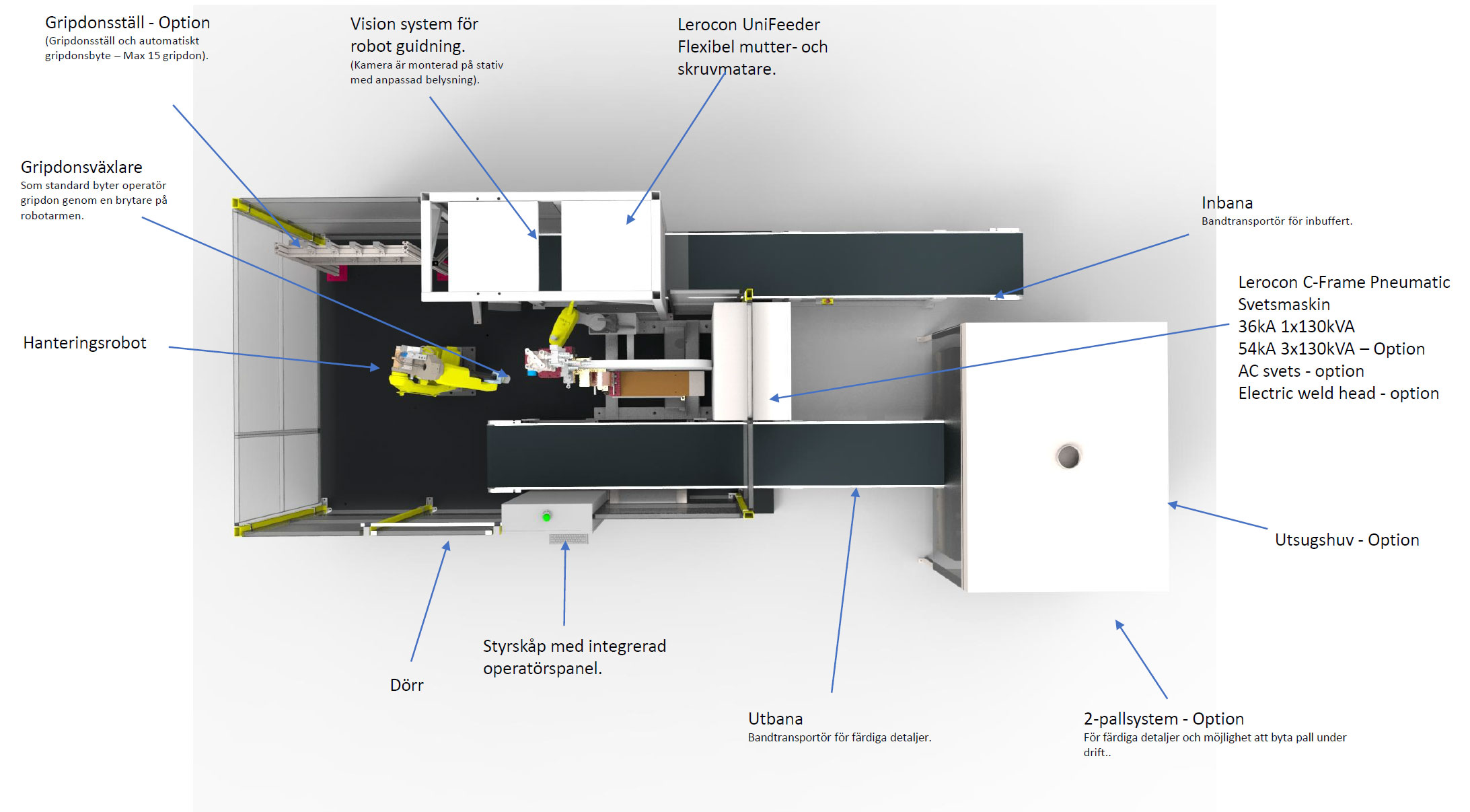

A modular and flexible detailed feed system from Lerocon, designed for fast installation, short cycle times and with features for maximum quality assurance and traceability.

Confeeder can be combined with other systems, products and available options from Lerocon.

Flow description

- The operator selects recipes on the operator panel and loads the track with detailed details

- The details are entered into vision systems that send picking coordinates to the robot

- The robot picks details from the track, welds all the nuts screws and puts finished details on the track

- Nuts are fed and loaded by Lerocon UniFeeder

The cell has high flexibility with the help of integrated vision systems and Lerocon UniFeeder for feeding large variety of fasteners!

The standard cell includes

- Robot ABB IRB 1600 or Fanuc M10iA

- Lerocon C-Frame Pneumatic 36kA, 1x130kVA MFDC weldmachine

- Lerocon GPR welding tools with a set of wear parts

- Lerocon UniFeeder flexible and fast feeder for fasteners

- Camera stand with lighting adapted for vision systems

- RSP gripper gear changers

- Lerocon HMI operator panel (Swedish and English version)

- Band conveyors for input and output buffer included quality enhancing features

- Ability to stack details on track

- Function for interval checking of details included in plc and robot program

- The fence included a door with a lock

- Cell built on removable platform for easy installation. Size adapted for container

- CE marking in accordance with current European machine directives

- Complete documentation and manual are delivered in digital format

- Testing at Lerocon’s premises before delivery

Available options:

- 2 pallet systems for changing pallets during operation.

- Extractor hood above stool

- Gripping down racks and automatic grab rails replacement.

- Welding machine with 54kA inverter and 3x130kVA transformer.

- AC Welding machine for welding demanding materials.

- Tailor-made grippers and welding tools.

- Turn key delivery with commissioning of customer-specific details.

- Cooler 5kW.

- Extra nut or screwdriver.

- Box handling of finished details.